Use of postbiotics and essential oil compounds in broilers

Postbiotics can help maintain immune strength and support antibiotic stewardship-promoting performance. Essential oil compounds enhance enzymatic activity in the GIT of broilers. Using them together can support broiler production performance and promote gut health.

ANTIBIOTIC REDUCTION SPECIAL 2023 – read all articles

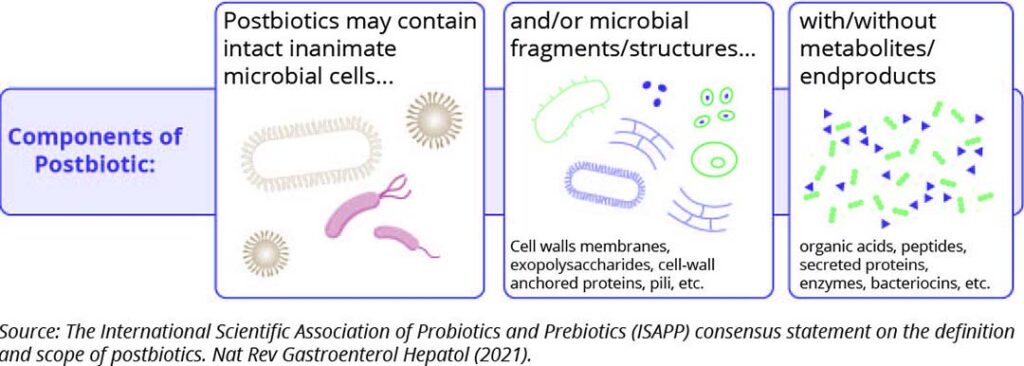

Postbiotics are widely known for their beneficial effects on various animals and humans. These are inanimate preparations from a controlled fermentation process that contain non-viable cells, various biologically active proteins, small peptides, oligosaccharides, vitamins, minerals, enzymes, and other unknown metabolites, conferring benefits to the host (Figure 1).

Figure 1 – Illustration of different components of postbiotics.

Postbiotics can help maintain immune strength, alleviate environmental stress responses, modulate the gut microbiome, and support gut integrity and nutrient absorption. Dietary inclusion of postbiotics can support antibiotic stewardship-promoting performance, welfare, and food safety in poultry production.

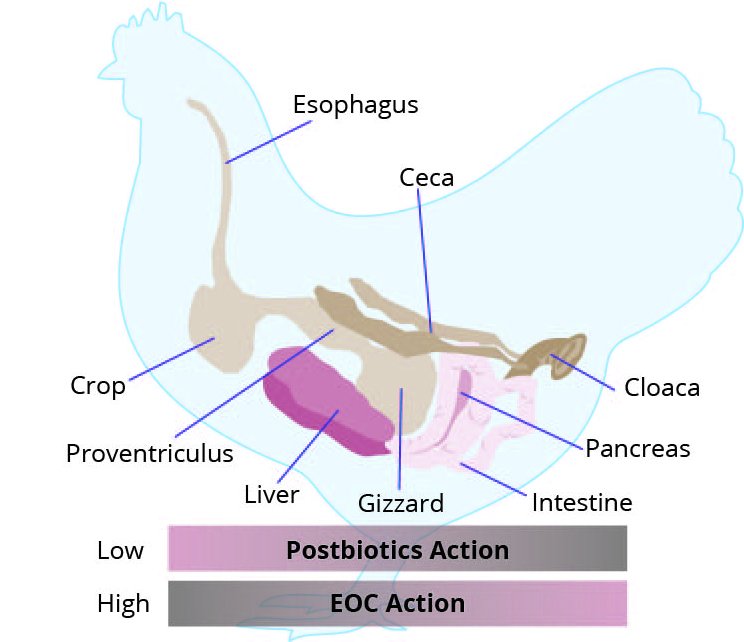

On the other hand, certain essential oil compounds (EOC) support improved enzymatic activity in the gastrointestinal tract of chickens, resulting in better digestion and absorption of nutrients. Although postbiotics and essential oils have been independently used in the poultry industry for a long time, little information is available on the potential synergies between these technologies (Figure 2).

Figure 2 – Synergy of postbiotics and essential oil compounds.

Synergy between postbiotics and EOCs

A unique combination of postbiotic Saccharomyces cerevisiae fermentation products (SCFP) and a proprietary blend of EOC in Dia-V MBPRO (MBPRO) (Diamond V Mills, Cedar Rapids, IA, USA) explored the synergy between the 2 technologies. The components of this product were selected based on years of research experience in screening different candidates and identifying the best combination for specific benefits in poultry. The EOC used in MBPRO supports enzymatic activity in the early part of the gut, whereas the SCFP component modulates the microbiome in the distal part of the gut. Testing the product using Cargill’s Galleon Broiler Microbiome Intelligence technology in broilers has shown advantages in promoting gut health by accelerating microbial maturation, helping minimise undesirable bacteria, and supporting beneficial bacteria.

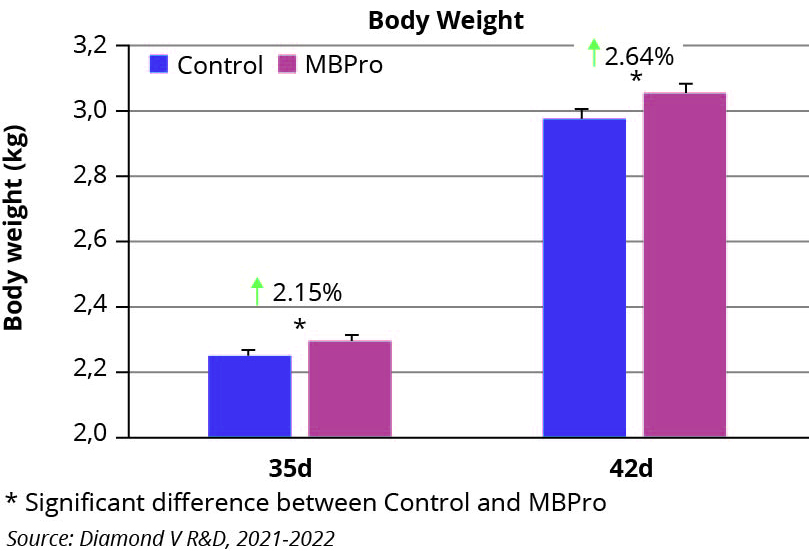

Figure 3 – Body weight – meta-analysis showing average across trials.

Multiple benefits of using postbiotic and essential oil compounds

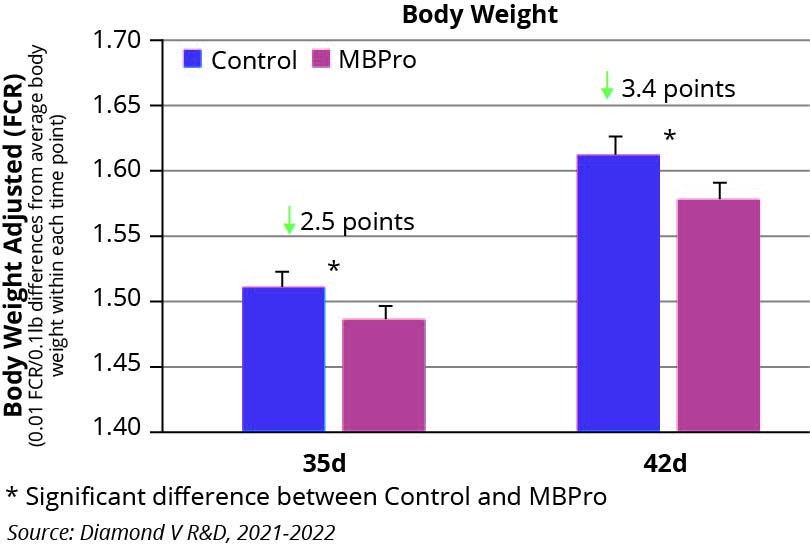

Eleven independent trials were conducted to evaluate the unique functionalities and benefits of using the poultry feed additive in broilers. Every trial contained 2 treatments, either the Control or the feed additive group, both receiving the same basal diet except for the inclusion of 0.4 kg/MT of the feed additive in the MBPRO group. Commercial broiler strains were fed corn-soybean-based diets, and data were collected at 36d (11 trials) and 42d (7 trials) of age, and various performance parameters were evaluated. Results from the meta-analysis showed that MBPRO birds had significantly improved weight (Figure 3) and body weight-adjusted feed conversion ratios (Figure 4) compared to the Control group at 35d and 42d of age. Interestingly, breast meat yield was improved by 0.5% in the birds fed the poultry feed additive (32.75%) compared to the Control (32.27%) birds at 42d. In conclusion, the meta-analysis of 11 independent studies demonstrated that the synergy between SCFP and EOCs in the poultry feed additive product supported broiler production performance, mainly by promoting gut health.

Figure 4 – Body weight adjusted FCR– Meta-analysis showing average across trials.

Conclusion

Poultry producers are challenged to do more with less today, while improving performance and profitability. To successfully meet the challenges of the industry, Cargill is committed to studying effects of different feed strategies and feed additives on bird production. Dia-V MBPRO is an example of the commitment Cargill is making to the poultry industry, and innovation we can offer.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht