Improving gut health with micro-encapsulation

Traditionally, the poultry industry has relied heavily on medicated feeds, including antibiotics, to promote growth and meat yield and counteract the negative impacts of enteric micro-organisms. Micro-encapsulation is a technology that can deliver optimal feed additives to improve overall gut health in poultry, while lessening the use of sub-therapeutic medicated additives in production.

ANTIBIOTIC REDUCTION SPECIAL 2023 – read all articles

The widespread and prolonged use of antibiotics has sounded alarms due to concerns over the emergence of antibiotic-resistant human pathogens in recent years. Consumers are clamouring for ‘clean label’ meats that are free from antibiotic residues and are willing to pay more for livestock and poultry that are raised in disease-free environments. For these reasons, controlling gut health across multiple species without the use of medicated feeds has become a key area of focus in product development. For humans, formulators are looking to take live probiotics into areas that were once unreachable. For animals, they seek to improve digestive processes in poultry and other monogastric organisms.

Clostridia and pathogenic coliform bacteria often associated with enteric diseases do not grow well in media with a low pH. Therefore, any means to reduce gut pH should improve an animal’s resistance to enteric diseases. Organic acids and their salts are currently presented as alternatives to lower gastric pH. Because organic acids and compounds such as zinc oxide have strong bacteriostatic effects, they have been used as salmonella-control agents in feed and water supplies. What if these compounds could be effectively delivered intact into the distal portions of the gastrointestinal tract?

Power of targeted delivery

Dietary organic acids are quickly neutralised in the duodenum unless they are delivered to the ileum and below with adsorbent vehicles. Maxx Performance has developed commercial preparations of slow-release micro-encapsulated blends of organic acids, essential oils and mineral compounds that deliver these non-medicated feed additives to the duodenum and beyond. They are being used to improve gut health in poultry and reduce the use of sub-therapeutic levels of antibiotics. In a recent farm trial turkey poults were fed diets containing slow-release micro-encapsulated essential oils versus a control group; mortality rates were 6.5% and 9.4%, respectively, reflecting a dramatic 67% reduction in mortality with micro-encapsulation.

Copper, which has effective antimicrobial properties, is protected through the gastrointestinal tract and released in the lower gut. Protecting each copper particle decreases the possibility of this mineral binding with other compounds to form complexes. Fewer pathogenic bacteria in the gut mean fewer harmful microbes to siphon off nutrients which, in turn, promotes better growth across different animal species. Feed manufacturers have used Maxx Performance slow-release micro-encapsulated copper in poultry diets to improve gut health and promote overall performance. In fact, slow-release copper sulphate as part of a poultry diet fed at 1-14 and 15-28 days to chickens resulted in thriftier birds, less diarrhoea and increased growth rates, plus better overall feed efficiency.

Using micro-encapsulated delivery systems and slow-release acidic modifiers can improve pH regulation in feed applications to prevent the colonisation of undesirable micro-organisms along the gastrointestinal tract. Targeted delivery can be used with a single component or a blend of several minerals and other ingredients that have demonstrated therapeutic effects. Micro-encapsulation technology has even enhanced the bio-availability of green tea extract for use as an effective anti-microbial in broiler diets. While green tea extract may be more expensive, micro-encapsulation allows poultry farmers to use less to obtain the same efficacy.

The relationship between gut microbiota and overall health cannot be overstated. As industries strive to reduce their dependence on medicated feeds, micro-encapsulation stands out as a powerful tool. This technology not only ensures the optimal delivery of feed additives but also paves the way for a future where poultry and other livestock can be raised in a healthier, more sustainable manner.

Slow-release acidic modifiers

Against this backdrop, Maxx Performance was approached by a transnational company looking for a way to deliver slow-release acidic modifiers to the intestines of poultry and pigs. They were using a competitor’s product that was clumpy, not free-flowing and inconsistent. Their goal was to reduce the amount of antibiotics in the feed and still achieve a steady growth rate. After two prototype developments and trials, the client reported that we had succeeded in producing a slow-release blend that met the company’s set criteria. Large-scale animal trials were positive and the products have since been commercialised.

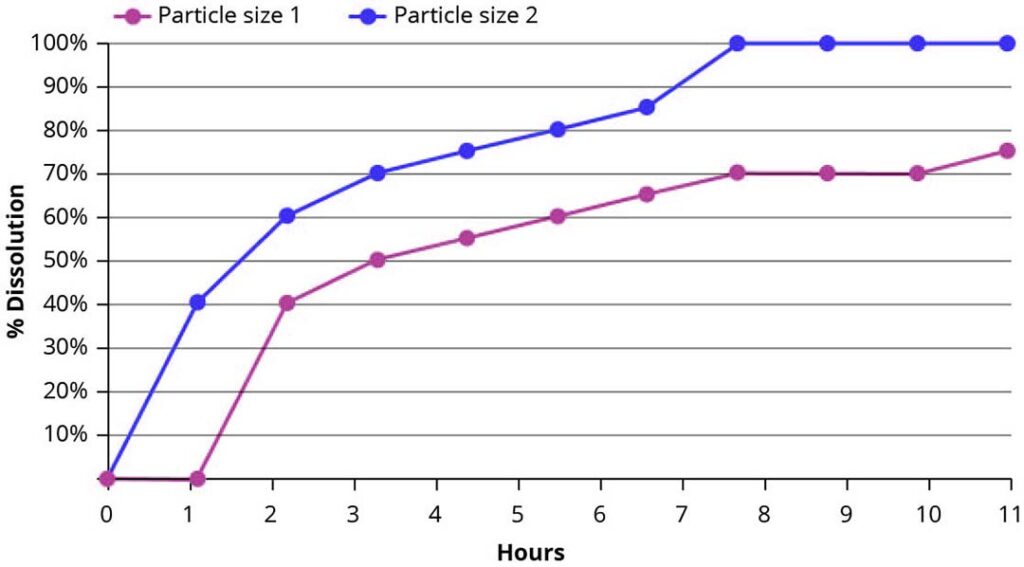

Figure 1 – Dissolution of micro-encapsulated organic acid by particle size distribution.

For effective delivery of slow-release compounds, Maxx Performance and partners have found that particle size affects the dissolution rate of compounds, such as minerals and others. For example, as shown in Figure 1, we achieved the goal of a 75-80% targeted release over 6 hours with particle size 2, which then has more application to animals with simple gastrointestinal tracts (monogastric), while particle size 1 is more suitable for animals with multiple stomachs (polygastric), where digestion takes longer.

The critical role of gut microbiota in health, especially gut health, is clear. Micro-encapsulation is a technology that can deliver the optimal feed additives, either as a single component or in combination, to improve overall gut health in poultry, other animals and humans, while lessening the use of sub-therapeutic medicated additives in production.

Future of poultry health

The dynamic relationship between gut microbiota and health, whether in poultry or in humans, underscores the importance of innovative options like micro-encapsulation. By ensuring targeted and optimal delivery of feed additives, this technology addresses two pressing concerns: improving gut health and reducing reliance on sub-therapeutic medicated additives. As the poultry industry evolves, so does the need for sustainable and effective health solutions. Micro-encapsulation offers a proven method of achieving these ends and promises a future where poultry is not only healthier but also raised in an environmentally-aware and sustainable manner.

References available on request.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht