S. African pig farmer successfully integrates smart Cloudfarms technology

One of South Africa’s leading pig farms has streamlined its business by adopting new technology that makes tedious management tasks much simpler, saving time and labour.

Based near Fochville in the Gauteng province, Taaibosch Piggery is a multi-tiered pig business run by the husband and wife team CP and Gerda Kriek. On top of the 2,300 commercial sow herd, the farm also runs a 300 sow nucleus breeding herd and has its own feed mill operation.

CP is very much an advocate of using new technology in agriculture, and 2 years ago was searching for software that would improve the operation of his farm.

Bringing Cloudfarms to Africa

During his extensive search he discovered the software offered by Danish specialist pig technology company, Cloudfarms, and knew it would be the perfect fit for his business. “In 2020 I started investigating new pig production software which has a strong traceability platform, mobile in-barn capturing ability and real time dashboards,” he said.

During his extensive search he discovered the software offered by Danish specialist pig technology company, Cloudfarms, and knew it would be the perfect fit for his business. “In 2020 I started investigating new pig production software which has a strong traceability platform, mobile in-barn capturing ability and real time dashboards,” he said.

“In addition, I needed production software that could be used for both the commercial and breeding units. I needed integration with my ESF system as well as genetic integration with our local Studbook and Genesus. I engaged with Cloudfarms and we found that our ideas and visions are aligned and it made sense to bring Cloudfarms to Africa.”

Being a multi-tiered pig production facility, Taaibosch Piggery has numerous daily records that need to be maintained by different staff members on the farm. Choosing the right software that was capable of all the tasks demanded by CP was of the utmost importance. By taking on the Cloudfarms software, CP is confident he made the right choice for his business. “I am confident in my decision to use Cloudfarms as I really did an in depth technology study and engaged with several suppliers.”

All-encompassing software

“For us, the main tasks demanded from the software start in the AI Station with boar evaluation and semen batching and also mobile service entry, farrowing events and individual animal ID creation, health treatments, movements and weighing/P2 measurements.

“We have subsequently developed a nice QR printing function with Cloudfarms and use the Gilt Selection Tools for genetic selection, the breeding orders for customer planning on the nucleus herd and all the way to shipping and the capturing of feed deliveries.

“For us, the medicine inventory and traceability is a very useful function to carry out weekly reconciliation and ensure food safety compliance. Since we use individual traceability on all animals, we can then link the carcass back to dam and sire level, which gives us good genetic selection capability,” said CP.

User-friendly

Cloudfarms highlights that one of the main benefits of its technology is the ease of data input, data access and how user friendly the software is for staff with varying skillsets.

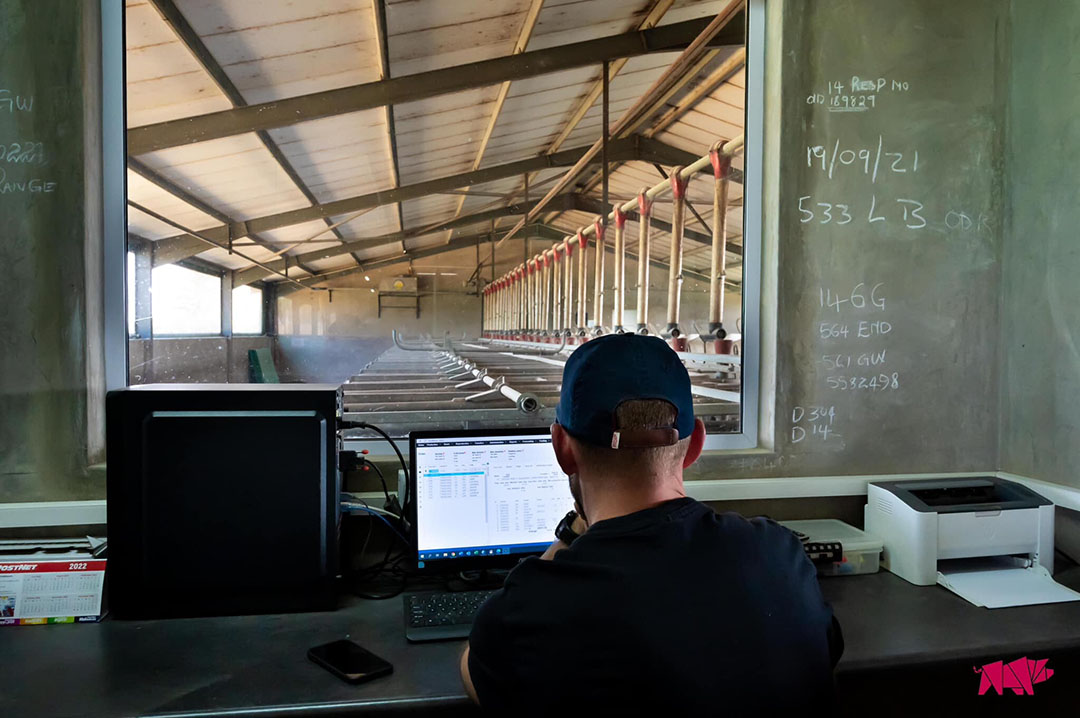

CP said: “It has reduced the double capturing of data, first in a book and then on the computer, while having managers spending more time in the barn than in the air-conditioned office.

“The accurate and quick capturing of data saves time at the end of the week or month to compile production reports, and the dashboards or reports are always available. The medicine function makes Quality Assurance compliance much easier.

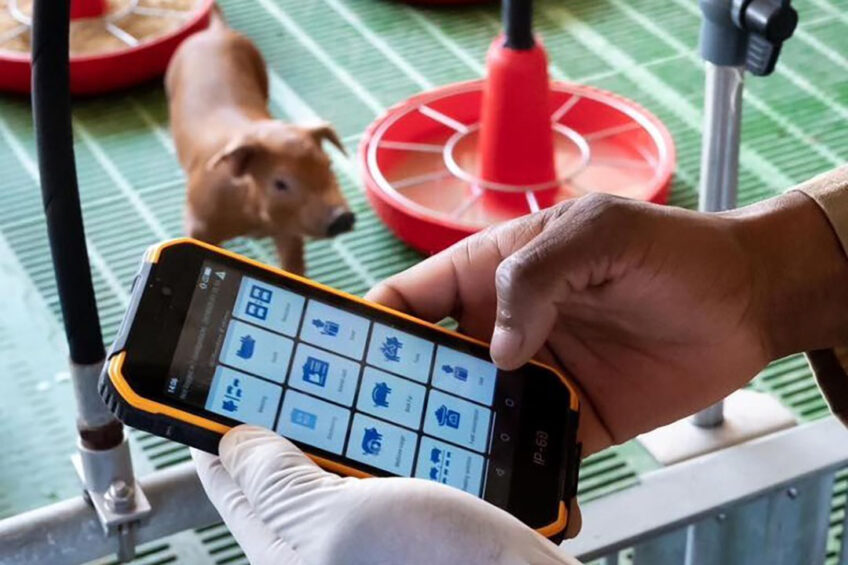

“We have quite a lot of mobile users in the farm, so I had to acquire a bunch of really tough farm-ready mobile devices, which are now used more and more for other functions as well.

A benefit to everyone on the farm

“There are about 26 mobile users who rotate phones as needed, and 8 web users who carry out selection, reporting and the solving of mobile issues,” he said.

Using the Cloudfarms technology was quite straightforward for the staff at Taaibosch Piggery following appropriate training. CP says the software has provided huge benefits for the staff.

Using the Cloudfarms technology was quite straightforward for the staff at Taaibosch Piggery following appropriate training. CP says the software has provided huge benefits for the staff.

“Now we have immediate feedback and can look up the data per animal,” said CP. “Plus, we have the ability to complete the data capturing part with the actual work. Previously we completed the work and then captured the entries.

“Double work is reduced, although it was a big transition from books to devices and for the established older staff it was quite challenging for them to accept that the data would not disappear.

“The functionality is straightforward once the setup and training is done well. We spent a lot of time with young professionals and the support team from Cloudfarms to do the planning and setup.

“Once the staff start to struggle or find too many problems and issues, they tend to lose motivation and revert back to their books.”

“A worthwhile investment”

Although it took time and money to introduce the Cloudfarms technology at Taaibosch Piggery, CP says it has been a worthwhile investment. “The software was expensive and took both time and money to implement, but our aim was not to save money short-term. This was an investment and improvement to the farm, especially a long-term vision to have more skilled labour, higher traceability and accuracy.

“I think the most time was saved by the staff and managers with regards to capturing data and looking up data in the office. Some decisions can now be taken faster in the barn.

“I think the most time was saved by the staff and managers with regards to capturing data and looking up data in the office. Some decisions can now be taken faster in the barn.

“Investing in the Cloudfarms technology did reduce my frustration levels. I can now view my production reports from anywhere at any time and know they are up to date and accurate instead of waiting for reports or compiling them myself.”

CP and his team have carried out further intensive work with the Cloudfarms development team to help create new functionality for the software and test it for them while in execution.

In the future, CP says he would like to see an improvement in the software genetic selection scorecard on both males and females to reduce the human error.

Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht